-

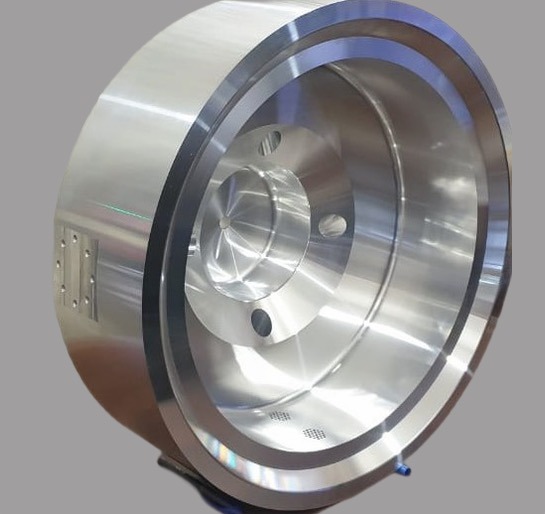

Project Work

VMC Milling -

3 Axis Work

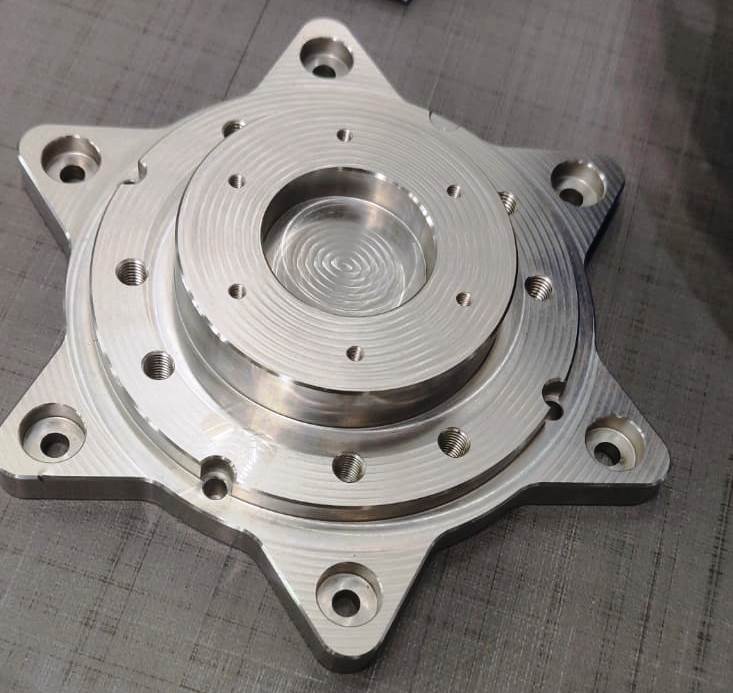

VMC Milling -

Aerospace Components

VMC Milling -

Diamond Machine Parts

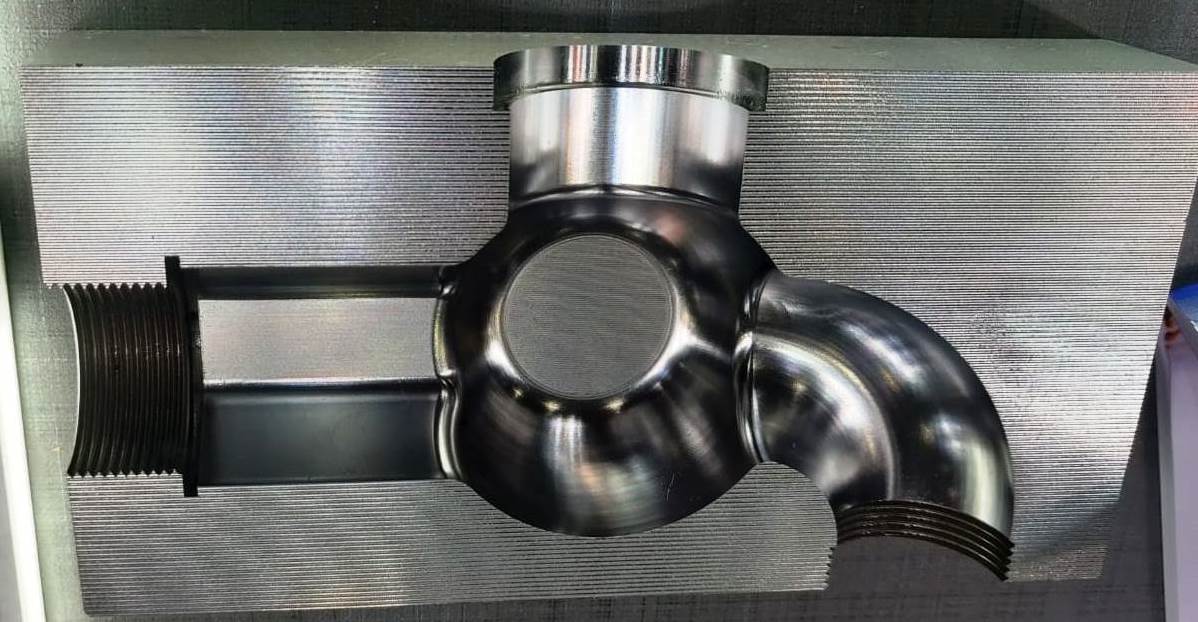

VMC Milling -

Customised Parts

VMC Milling -

Dies

VMC Milling -

Jig & Fixtures

VMC Milling -

Mould Machining

VMC Milling

VMC Milling

MACHINE MAKE | MACHINE | WORKING RANGE | EXTRA AXIS | YOM |

LMW | JV CRAFT | 800X450X500mm | 5TH AXIS | 2020 |

AMS | MCV 650 | 1020X650X650mm | 4TH AXIS | 2017 |

AMS | MCV 450 | 800X450X450mm | – | 2019 |

AMS | 430 V | 400X300X300mm | – | 2021 |

Our VMC milling process produces custom prototypes and end-use production parts in as fast as 1 day. We use 3-axis, 4th axis simultaneous and 5-axis synchronise milling processes to manufacture parts from more than 30 engineering-grade plastics and metals. KEYTEX MACHINES VMC machining service can deliver machined parts in less time than it takes to get a quote from other traditional machine shops. Upload a CAD file, choose the material and part quantity, and tell us when you need the parts.

Full form of VMC

The full form of VMC in the context of machining typically refers to “Vertical Machining Center.” A Vertical Machining Center is a type of milling machine where the spindle axis is vertically oriented. This configuration allows for the machining of parts from the top down, and the workpiece is typically held in a vertical position on the machine table. VMCs are widely used in manufacturing for tasks such as milling, drilling, and tapping, and they are known for their versatility in producing a variety of complex parts with high precision.

What is VMC Machining?

VMC machining refers to the process of using a Vertical Machining Center (VMC) to manufacture parts and components. A Vertical Machining Center is a type of milling machine where the spindle axis is oriented vertically. This design allows for the machining of parts from the top down, and the workpiece is typically secured to the machine table in a vertical position.

In VMC machining, the machine tool is controlled by computer numerical control (CNC), and the machining operations are guided by a pre-programmed set of instructions. These instructions, often written in G-code, dictate the movements and actions of the cutting tools as they remove material from the workpiece to achieve the desired shape and dimensions.

Use of VMC Milling machine?

Vertical Machining Centers (VMCs) are widely used in manufacturing for a variety of applications due to their versatility, precision, and efficiency. Here are some common uses of VMC milling machines:

- Milling Operations: VMCs are primarily used for milling operations, which involve removing material from a workpiece to create a specific shape or feature. This can include contouring, profile milling, face milling, and other milling processes.

- Drilling: VMCs can be equipped with drill bits to perform drilling operations on workpieces. This is commonly used to create holes of different sizes and depths in metal, plastic, or other materials.

- Tapping: VMCs can be used for tapping operations, where threads are cut into a hole. This is important for creating threaded connections in parts.

- Engraving and Surface Finishing: VMCs equipped with appropriate tooling can be used for engraving and surface finishing operations. This is crucial for adding detailed markings or achieving a specific surface texture on the workpiece.

- Prototyping: VMCs are often employed in the prototyping process to create prototypes of parts before full-scale production. The ability to quickly and accurately machine prototypes allows for testing and validation of designs.

- Production of Complex Parts: VMCs are capable of machining complex and intricate parts with high precision. This makes them suitable for industries that require the production of intricate components, such as aerospace, medical, and electronics.

- Mold Making: VMCs are commonly used in mold making for industries such as plastic injection molding. The precision and accuracy of VMCs are essential for creating molds that will produce high-quality parts.

- Automotive Manufacturing: VMCs play a crucial role in the production of automotive components, including engine parts, transmission components, and chassis parts. The ability to machine precise and complex shapes is essential in the automotive industry.

- Aerospace Manufacturing: In the aerospace industry, VMCs are used for machining components like aircraft structural parts, engine components, and other critical parts that require high precision and reliability.

- Electronics Industry: VMCs are used in the production of electronic components, including the milling of circuit boards and the machining of parts for electronic devices.

The flexibility and capability of VMC milling machines make them suitable for a wide range of applications across various industries. They have become a standard tool in modern manufacturing facilities, contributing to increased efficiency and the production of high-quality components.

How many axes are there in VMC Milling?

Vertical Machining Centers (VMCs) can have different numbers of axes depending on their configuration and capabilities. The three most common types of VMCs are 3-axis, 4-axis, and 5-axis machines. Here’s an explanation of each:

- 3-Axis VMC: A 3-axis VMC is the most basic type, with three linear axes – X, Y, and Z. These axes correspond to the horizontal, vertical, and depth movements of the cutting tool. The machine can move in these three directions to perform milling, drilling, and other operations. A 3-axis VMC is suitable for many standard machining tasks.

- 4-Axis VMC: In addition to the three linear axes (X, Y, and Z), a 4-axis VMC introduces another rotational axis, often referred to as the A-axis. The A-axis allows the workpiece to be rotated, enabling the machine to access different faces of the part without repositioning it. This is useful for more complex machining tasks and can be beneficial in reducing setup times.

- 5-Axis VMC: A 5-axis VMC adds another rotary axis, typically the B-axis, to the three linear axes (X, Y, and Z) and the A-axis. This additional axis allows the cutting tool to tilt or swivel, providing even greater flexibility in machining. With a 5-axis VMC, complex geometries and contours can be machined with a single setup, reducing the need for multiple fixture changes.

The number of axes in a VMC affects its capability to handle different types of machining tasks and the complexity of the parts it can produce. While 3-axis machines are suitable for many applications, 4-axis and 5-axis machines offer increased versatility and the ability to tackle more intricate workpieces with fewer setups. The choice of the number of axes depends on the specific requirements of the machining tasks and the complexity of the parts being produced.

Advantages of VMC Machining Over Conventional Machining

Vertical Machining Center (VMC) machining offers several advantages over conventional machining methods, such as manual milling or turning. Here are some of the key benefits:

- Automation and Precision:

- CNC Control: VMCs are computer numerical control (CNC) machines, allowing for precise control and automation of the machining process. This results in higher accuracy and repeatability compared to manual machining.

- Consistent Quality: The automated nature of VMC machining ensures consistent quality in the produced parts, reducing the variability introduced by manual operations.

- Versatility:

- Multi-Axis Capability: VMCs can have multiple axes (3-axis, 4-axis, or 5-axis), providing increased flexibility for machining complex geometries. This versatility allows for the production of a wide range of parts with varying shapes and features.

- Various Machining Operations: VMCs can perform a variety of machining operations, including milling, drilling, tapping, and more. This versatility makes them suitable for a broad range of applications across different industries.

- Efficiency and Productivity:

- Faster Machining: VMCs can operate at higher speeds compared to manual machining, leading to faster production cycles.

- Reduced Setup Time: CNC programming and automated tool changes in VMCs contribute to faster setups, reducing downtime between different machining operations.

- Complex Geometry and Intricate Parts:

- 5-Axis Machining: VMCs with 5-axis capability can machine complex geometries in a single setup, eliminating the need for repositioning the workpiece. This is especially beneficial for industries requiring intricate and highly detailed components.

- Cost-Effectiveness:

- Reduced Labor Costs: Automation in VMC machining reduces the need for manual labor, leading to cost savings in terms of labor expenses.

- Lower Scrap Rates: The precision and repeatability of VMCs contribute to lower scrap rates, reducing material waste and associated costs.

- Improved Tool Life:

- Optimized Cutting Parameters: CNC programming allows for the optimization of cutting parameters, leading to improved tool life. This results in reduced tool replacement costs and increased overall efficiency.

- Quality Control:

- In-Process Monitoring: VMCs can be equipped with sensors for in-process monitoring and quality control, allowing for real-time adjustments and ensuring that parts meet specified tolerances.

- Adaptability to Modern Manufacturing Needs:

- Integration with CAD/CAM: VMCs easily integrate with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, enabling seamless design-to-production workflows.

In summary, VMC machining provides advantages in terms of precision, efficiency, versatility, and cost-effectiveness compared to conventional machining methods. These benefits make VMCs a preferred choice for modern manufacturing processes, especially in industries that demand high-quality, complex components.

What are VMC machining products?

Vertical Machining Centers (VMCs) are used to manufacture a wide range of products across various industries. The versatility of VMC machining makes it suitable for producing different types of components with high precision. Here are some examples of products that can be manufactured using VMC machining:

- Aerospace Components:

- Aircraft structural parts

- Engine components

- Landing gear components

- Automotive Parts:

- Engine blocks and cylinder heads

- Transmission components

- Suspension parts

- Brake components

- Electronics and Technology:

- Enclosures for electronic devices

- Heat sinks

- Connectors and housings

- Medical Devices:

- Surgical instruments

- Implant components

- Prosthetics and orthopedic devices

- Tool and Die Components:

- Mold and die components

- Cutting tools

- Toolholders

- Consumer Goods:

- Smartphone and tablet components

- Consumer electronics parts

- Components for appliances

- Energy Sector:

- Wind turbine components

- Parts for power generation equipment

- General Machinery Parts:

- Gearboxes and gears

- Shafts and couplings

- Pump and valve components

- Custom and Prototyped Parts:

- One-off or small-batch custom parts

- Prototypes for product development

- Specialty components for specific applications

- Mold Making:

- Injection molds for plastic parts

- Die casting molds

- Defense and Military Components:

- Firearms components

- Military vehicle parts

These examples highlight the diverse range of products that can be manufactured using VMC machining. The ability of VMCs to handle various materials, such as metals, plastics, and composites, coupled with their precision and flexibility, makes them a preferred choice for the production of complex and critical components in modern manufacturing. The specific applications can vary widely depending on the industry and the requirements of the end-use product.

What is the price structure of VMC machining work?

The pricing structure for Vertical Machining Center (VMC) machining work can vary significantly based on several factors. It’s important to note that the cost of VMC machining is influenced by a combination of machine-related expenses, material costs, labor, and other associated factors. Here are key factors that contribute to the pricing structure:

- Machine Time:

- The primary factor in VMC machining costs is the machine time required to complete the job. This includes the time it takes to set up the machine, load the program, and execute the machining operations.

- Complexity of the Part:

- More complex parts with intricate designs and tight tolerances generally require additional programming time and may involve longer machining times. This complexity can impact the overall cost.

- Material Costs:

- The type and cost of the material being machined play a significant role in pricing. Exotic or high-performance materials often come with higher material costs.

- Tooling Costs:

- The cost of cutting tools and tool changes during the machining process can contribute to the overall expense. Specialized tooling for specific jobs may also incur additional costs.

- Number of Setups:

- Jobs that require multiple setups may have increased labor costs and setup times. The more setups involved, the more time and resources are required.

- Tolerances and Quality Requirements:

- Tight tolerances and high-quality standards may necessitate additional care, precision, and inspection, which can impact the overall cost.

- Batch Size:

- The quantity of parts being produced can affect the pricing structure. Larger production runs may benefit from economies of scale, potentially reducing the per-part cost.

- Labor Costs:

- Labor costs include the time spent on programming, setup, monitoring, and any manual operations involved. Skilled labor may come at a higher cost.

- Overhead and Operating Costs:

- Overhead costs, including facility expenses, machine maintenance, utilities, and other operational costs, are factored into the overall pricing structure.

- Market Rates:

- Market conditions and local economic factors can influence pricing. Rates may vary based on geographic location and industry demand.

- Additional Services:

- Any additional services, such as finishing, coating, or assembly, can contribute to the overall cost.

Given the variability of these factors, it’s common for machining shops to provide customized quotes based on the specific requirements of the customer’s project. It’s advisable to communicate clearly with the machining service provider to ensure an accurate and transparent pricing structure that meets the project’s needs and quality standards.

Why VMC machining is mandatory for precise machining?

Vertical Machining Center (VMC) machining is considered mandatory for precise machining in many applications due to several key advantages that it offers over conventional machining methods. Here are some reasons why VMC machining is often essential for achieving high precision in manufacturing:

- CNC Control:

- VMCs are equipped with Computer Numerical Control (CNC) systems that allow for precise and accurate control of the machining process. CNC technology ensures consistency and repeatability in producing complex geometries.

- High Accuracy and Repeatability:

- VMCs can achieve tight tolerances and high precision, thanks to the precise control of the tool movement along multiple axes. This level of accuracy is crucial for industries where parts must meet strict specifications.

- Multi-Axis Capability:

- VMCs are available in configurations with multiple axes (3-axis, 4-axis, or 5-axis), allowing for the machining of complex shapes and contours in a single setup. This reduces the need for repositioning the workpiece, minimizing errors and ensuring precision.

- Reduced Human Error:

- Automation in VMC machining reduces the reliance on manual labor, minimizing the potential for human errors in the machining process. CNC programming ensures that the machine follows precise instructions consistently.

- Optimized Cutting Parameters:

- CNC programming in VMC machining allows for the optimization of cutting parameters, such as cutting speed, feed rate, and toolpath. This optimization contributes to improved tool life and consistent machining results.

- Tool Changes and Automatic Tool Compensation:

- VMCs often feature automatic tool changers that enable the machine to switch between different cutting tools without manual intervention. Additionally, CNC control allows for automatic tool compensation, ensuring accurate tool positioning during machining.

- Top-Down Machining:

- The vertical orientation of the spindle in VMCs allows for efficient top-down machining, where the cutting tool moves vertically into the workpiece. This orientation facilitates chip evacuation and contributes to improved surface finish and precision.

- Versatility in Materials:

- VMCs can machine a wide range of materials, including metals, plastics, and composites, with high precision. This versatility makes them suitable for various industries with diverse material requirements.

- In-Process Monitoring and Quality Control:

- VMCs can be equipped with sensors for in-process monitoring, allowing for real-time adjustments and ensuring that parts meet specified tolerances. Quality control features contribute to maintaining precision throughout the machining process.

- Efficient Programming with CAD/CAM Integration:

- VMCs integrate with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, enabling efficient programming of complex geometries. This integration ensures that the machined parts accurately reflect the design intent.

In summary, the combination of CNC control, multi-axis capability, automation, and optimized cutting parameters makes VMC machining essential for achieving high precision in modern manufacturing. The technology is well-suited for applications where accuracy, consistency, and the ability to produce complex parts are critical requirements.